How to Identify Top Injection Molding Services in China

So, the big meeting just wrapped up. your new project has the green light, the timeline is aggressive, and the budget is… well, let’s just say it’s tight.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Of course, you acknowledge. It makes sense on paper. The potential savings can be massive. Yet your thoughts are already spinning. You know the rumors, don’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

But here’s the catch. Sourcing plastic mold can be a calculated project. It’s a project, just like any other. And its outcome hinges on the approach you take. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Ignore the nightmare anecdotes. Let’s walk through a real-world playbook for getting it right.

First Things First: Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. You can’t expect a factory on the other side of the world to read your mind. Sending a vague request is like asking a builder to quote you for “a house.” The replies will range from absurdly low to exorbitant, none of which help.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. It’s the cornerstone of your entire effort.

What should you include?

Start with your 3D design files. They’re essential. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This is the master blueprint for your part’s geometry.

Yet 3D models don’t cover everything. You also need detailed 2D drawings. This is where you call out the stuff that a 3D model can’t communicate. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. Call out smooth surfaces or precision hole sizes in big, bold notation.

Then specify the material. Avoid generic terms like “Plastic.” Even “ABS” alone is too vague. Be explicit. Call out SABIC Cycolac MG38 (black), for example. Why be exact? Because there are thousands of plastic variations. Defining the exact material guarantees the performance and appearance you designed with plastic mold injection.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

Don’t forget the commercial info. What’s your forecasted annual volume (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? The tool design, the number of cavities, and the price per part all hinge on this number.

Finding the Right Supplier

With your RFQ perfected, who will you target? The internet has made the world smaller, but it’s also made it a lot noisier. It’s easy to find a supplier; it’s hard to find a good one.

Your search will likely start on platforms like Alibaba or Made-in-China.com. These are great for casting a wide net and getting a feel for the landscape. Use them to build a shortlist, not the final list. Aim for a preliminary list of 10–15 potential partners.

However, don’t end your search there. Consider using a sourcing agent. True, they charge a fee. Yet top agents deliver reliable, audited suppliers. They bridge language and cultural gaps. As a newcomer, this offers priceless security. Consider it timeline insurance.

Another classic method? Trade shows. With budget permitting, Chinaplas or similar shows are invaluable. Nothing beats a face-to-face conversation. Hold samples, talk shop, and gauge professionalism firsthand. Also, leverage the tried-and-true referral network. Consult trusted colleagues. A solid referral can be more valuable than any ad.

Sorting the Contenders from the Pretenders

After firing off that RFQ to a broad pool, the quotes will start trickling in. Some prices will undercut logic, others will shock you. Now, sift through and shortlist 2–3 reliable candidates.

How to proceed? It blends technical checks with intuition.

Step one: audit communication. Are their replies prompt and clear? Do they communicate effectively in English? The true litmus: are they raising smart queries? Top vendors will critique and inquire. Example: “Should we add draft here for better ejection?” or “Your tolerance may require extended CMM time—okay?” That’s a huge positive sign. It proves their expertise and involvement. A “Sure, no issues” vendor often means trouble.

Then confirm their machinery specs. Get their tooling inventory. Review examples of parts akin to your design. Don’t pick a micro-molding shop for large components.

Finally, inspect the factory. Skipping this is a mistake. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They’ll send a local inspector to the factory for a day. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. That small investment can save you thousands.

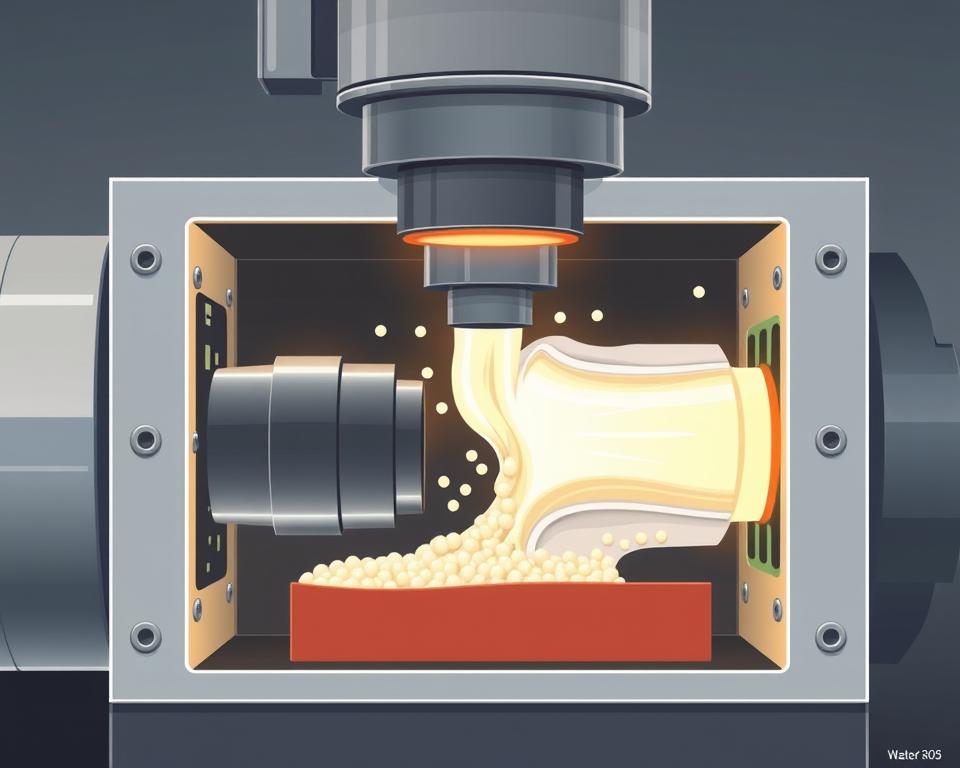

Converting Digital Designs into Molded Parts

Once you’ve chosen your supplier. you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Now the process kicks off.

Initially, expect a DFM report. Design for Manufacturability (DFM) is essential. It’s the engineering critique for moldability. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. Comprehensive DFM equals a top-tier supplier. It’s a collaboration. You iterate with their team to optimize the mold.

Once the DFM is approved, they’ll start cutting steel to make your injection mold tool. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are your initial mold shots. It’s your test of success.

Be prepared: T1 samples are almost never perfect. That’s standard process. There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold company samples. It could require several iterations. Build buffer time for sample iterations.

Finally, a flawless part arrives. It matches all specs, has a pristine finish, and works as required. This is now the benchmark sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Completing the Sourcing Journey

Receiving the golden sample seems like victory, but you’re not done. Now comes full-scale production. How can you keep part #10,000 matching your golden sample?

Put a strong QC process in place. Often, you hire a pre-shipment inspection service. Use a third-party inspector again. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. You receive a full report with images and measurements. Only after you approve this report do you authorize the shipment and send the final payment. This simple step prevents you from receiving a container full of scrap metal.

Lastly, plan logistics. Understand the shipping terms, or Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, where you handle everything from their gate? These choices hugely affect landed cost.

China sourcing is a long-haul effort. It relies on partnership-building. View them as allies, not vendors. Transparent dialogue, respect, and process discipline win. Certainly, it’s complex. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re ready.